ADVANTAGES: Increases gas velocity • Low-pressure drop • Up to 99% Separation efficiency • Improves gaseous phase quality • No loss of liquid phase products • No limitation in size & shape • Easy to erect • No maintenance or services.

APPLICATIONS: Vacuum Towers, Lube Towers, Distillation Towers, Evaporators, Absorbers, Regenerators, Scrubbers, Strippers, Steam Drums, Moisture Separators, Ventilation Systems, Flam Arrestors etc.

MATERIAL OF CONSTRUCTION: Metals i.e. SS 304, 304L, 316, 316L, 321, 430, Nickel, Monel, Inconel, Incolloy, Hastalloy, Alloy 20,Copper and Plastics Polypropylene, Nylon, Teflon (FEP/PTFE) & Hostaflon.

DESIGN CONSIDERATION: The initial design factor is the velocity of gas through the blanket. If it's too high than separated droplets will re-enter in gas flow by flooding through of mesh blanket. If too low, droplet passes without impingement.

The equation to calculate Allowable optimum velocity = V= K*sqrt(DL-DG/DG)

Where: DL= Liquid density ? Dg= Gas Density G K= System Constant (0.11).

Higher separation efficiency can be obtained by maintaining velocity range up to 30 t0 110% by above equation. Pressure drop remains in negligible range of less than 25 mm H2O (WC).

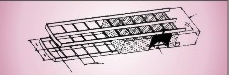

MECHANICAL DESIGN: MISTER-MESH PADS are manufactured in single piece duly wounded in coiled form for smaller diameter vessels up to 500 mm and manufactured in mattresses form in segments for larger diameter vessels above 500 mm. Segments are designed for easy pass through manhole, easy to lift, move and handle, easy to tie by using fixing wire or fasteners.

MECHANICAL DESIGN: MISTER-MESH PADS are manufactured in single piece duly wounded in coiled form for smaller diameter vessels up to 500 mm and manufactured in mattresses form in segments for larger diameter vessels above 500 mm. Segments are designed for easy pass through manhole, easy to lift, move and handle, easy to tie by using fixing wire or fasteners.

SUPPORT GRID provided at top & bottom of MISTER-MESH PADS has above 90% free area. Grids helps mesh blanket remain fix on vessel cleat/rings to works suitably against fluctuated operation conditions. Grids are normally made out of 25x3 mm thick flats and 6 mm Ø rods in metals and out of 25x5 mm flats in plastic.

SUPPORT GRID provided at top & bottom of MISTER-MESH PADS has above 90% free area. Grids helps mesh blanket remain fix on vessel cleat/rings to works suitably against fluctuated operation conditions. Grids are normally made out of 25x3 mm thick flats and 6 mm Ø rods in metals and out of 25x5 mm flats in plastic.INSTALLATION: suitable clearance height must be maintained under and above the pads ?For pad diameter below 500 mm, clearance should be equal to pad diameter. ? for pad diameter up to 2000 mm, it shall be 500 mm under and above respectively ?for diameter up to 6000 mm it shall be 800 to 1000 mm under and above respectively.

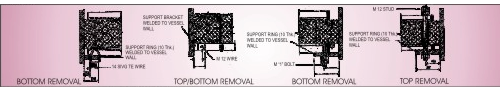

FIXING: MISTER-MESH Pads with grids are fixed with vessel cleat or annular ring by using fixing wires, Fasteners i.e. 'J' Bolts (bottom removal) or Bolts (top removal). If diameter of pad is more than 1500 mm than one or more 'I' beams is provided. Maximum distance of 1 to 1.3 M can be maintained between two beams.