MISTER MESH VAN/ZIG ZAG PLATE ELIMINATORS

are used to separate viscous, suspended solid or large droplet size vapors. Van mist eliminators provided high efficiency at low-pressure drop compare to mesh blanket type eliminators, which is not advisable to use due to possibility of chocking & plugging. This eliminator is made out of 0.5 to 1mm thick plates in zigzag shape with 2 to 3 pass. These plates are arranged in parallel at a distance of

20 to 40 mm to obtain maximum contact. Spacer bars or bolting arrangements are made at top & bottom of eliminator to hold each vans/plates.

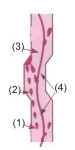

When vapors enter to eliminators(1). It travels through zigzag passage of plates(2). Entrained droplets strikes on plate surfaces and get separated(3). Most mist gets separated in first pass where rest gets separated in subsequent passes. Separated droplets coalesce and convert in large droplets and falls down to drain(4).

ADVANTAGES: • For very sticky or viscous droplets • Solid fouling • High size droplets • high velocity • easy to clean • long life • high resistance to corrosive liquid.

APPLICATION: • Distillation Columns • Scrubbing towers • Evaporators • Knock Out Drums • Flam Arresters etc.

MATERIAL OF CONSTRUCTION: Carbon Steel, All 300 & 400 series of SS, Monel, Inconel, Incoloy, Hastalloy, Ally 20, Nickel, 904L etc.

COMBINED MIST ELIMINATORS is the effective solution for high liquid load vapors & carry over with fine suspend particles. This mist eliminator is combination of Van type & Mesh Blanket type mist eliminators where van type act as a first stage separator and mesh blanket is final stage separator. Van separator removes the large size droplet sand solid particles than fine mist are separated by mesh blanket pad.

These eliminators are manufactured in all metal and alloy in any sizes.

20 to 40 mm to obtain maximum contact. Spacer bars or bolting arrangements are made at top & bottom of eliminator to hold each vans/plates.

20 to 40 mm to obtain maximum contact. Spacer bars or bolting arrangements are made at top & bottom of eliminator to hold each vans/plates.