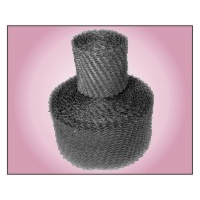

MULTIMESH COLUMN PACKINS is high efficiency knitted and crimped multifilament wire gauge structure packing. It has high surface contact area, low pressure drop per theatrical stage, low H.E.T.P. value and less energy consumption compare to random and woven wire gauge packing. It ideal packing for fractional distillation column for separation of value added product, heat sensitive materials and close boiling point materials which require many theoretical stages at low pressure or atmospheric pressure. Ithas excellent self-distribution property due to knitted and crimped construction, which provides dense passage to promote continuous division and re combination of vapors.

ADVANTAGES: • High distillation efficiency. • Low-pressure drop as low as 0.1 to 1 mm Hg per theoretical stage.• Low H.E.T.P. as low as 4 to 6 inches that reduces column systems • Self-redistribution capacity due to inherent capillary action •; Improves product purity.• High turn down ratio • Available in most Metals & Alloys material.

APPLICATIONS:• High Vacuum Columns Pilot Plants. • Pharmaceuticals & Fine Chemicals. • Flavor and fragrance compounds Fatty acid, Amides & alcohols. • Close boiling point components. • Plasticizer esters.

COMPARISON WITH OTHER PACKING:

| Property | Multimesh Packing | 25mm Raching Ring(Metal) | 25mm Pall Ring(Metal) |

|---|---|---|---|

| Bulk Density | 432Kg/M³ | 495Kg/M³ | 400Kg/M³ |

| Contact Area | 1950 M²/M³ | 200 M²/M³ | 209 M²/M³ |

| Free Volume | 94.6% | 91.9% | 94.2%) |

| Pressure Drop | 0.1 to 1.0 MM Hg | 0.1 to 1.0 MM Hg | 0.1 to 1.0 MM Hg |

| HETP Value | 100 to 150 mm | 450 mm | 350 mm |